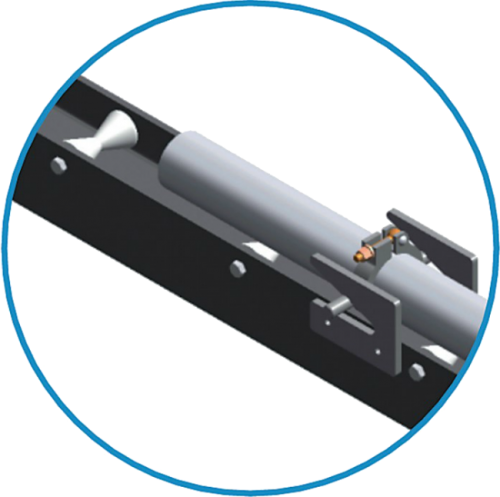

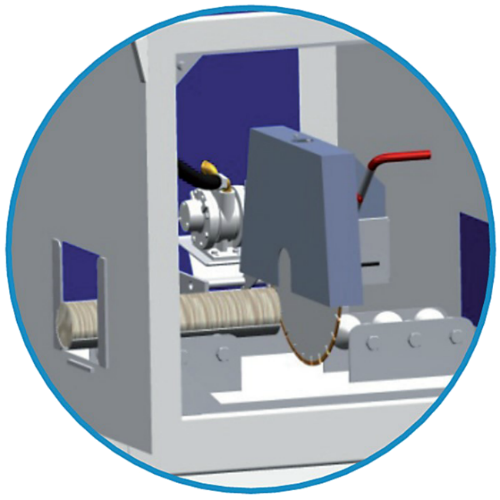

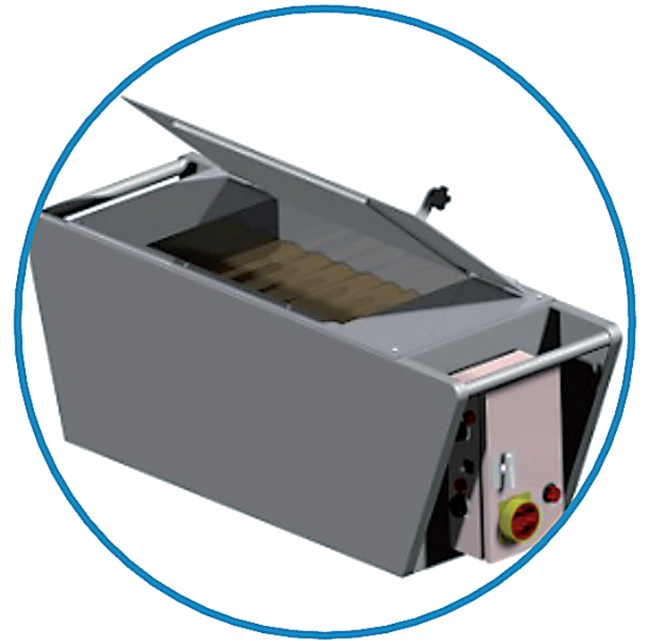

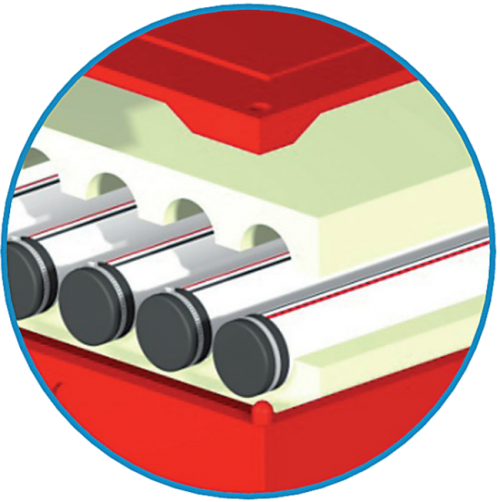

Core Craddle

Improper procedures may result in severe damage. Mechanical damage can be caused due to either shocks or flexion. This can alter properties of the entire

length.

To avoid this issues, Christensen provides the Core Craddle to protect the core sample and ensures the length of core remains rigid as it is moved to the catwalk and/or core processing site.

The Core craddle has 9mts long to Core Full-lenght protection.

Español

Español