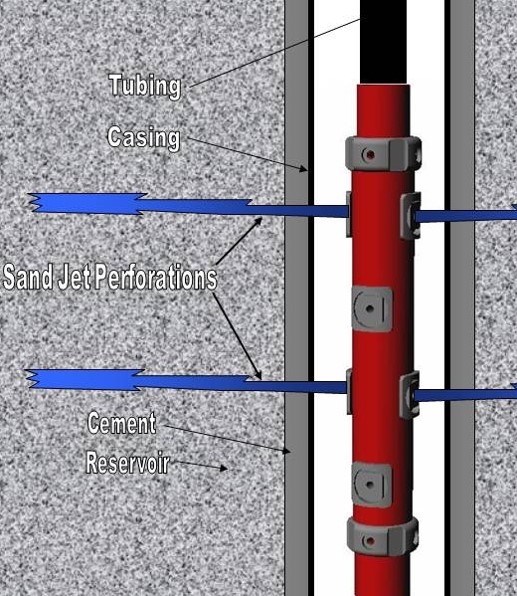

Sand jet perforating (SJP) is a process that uses high pressure fluid slurry to perforate tubulars and cement within an oil or gas well, and simultaneously extend a cavity into the reservoir. Newer modular SJP tool designs ensure near limitless re-configuration of coiled tubing conveyed plugs, packers, hold-down tools, perforation, and fracturing tools for simultaneous use during completion and work-over operations.

Applications for Sand Jet Perforating technology include perforation and re perforation of vertical and horizontal oil and gas wells and perforation and treatment of coal bed methane wells. SJP can also be used in conjunction with other technologies such as fresh water and foam fracturing and for enhanced performance resulting from chemical injection and acidization. Sand Jet Perforating provides an alternative to widely accepted wire-line or tubing conveyed explosive methods used in most fields today.

Hundreds of documented successes are available to confirm that SJP increases

communication between well bore and reservoir more effectively with less formation damage and is accomplished in fewer round trips in and out of the well bore than more widely used perforating methods. Added benefits are realized as perforating and fracturing can be accomplished nearly simultaneously with a common work string.

Sand Jet Perforator

The Sand Jet Perforator is the backbone of the TD Tools selection of patented abrasive cutting tools. Sand Jet Perforating (SJP) is an alternative to traditional explosive perforating methods, that uses high pressure abrasive fluids to perforate the casing and extend a cavity into the reservoir.

FEATURES

- Can be run on Coiled tubing or Jointed Pipe.

- Allows to make Perforations and Acid Stimulation in the same run.

- Available in Many Phasing Patterns, shot density and orifice diameters.

- Built in Carbide Tungsten Protective Plates to protect the tool body from washback.

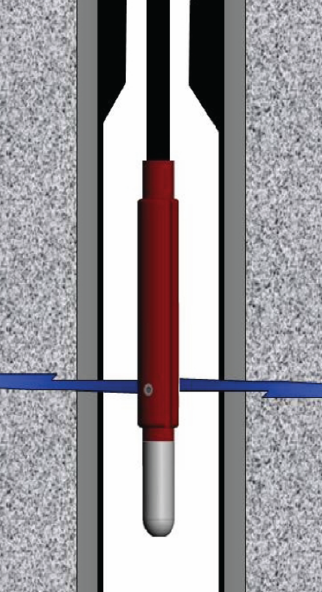

UltraSlim Sand Jet Perforator

The Ultraslim SJP New Design Allows Interchangeable Redress Parts in an Extremely Small Size to perform perf operations through restrictions.

FEATURES

- Can be run on Coiled tubing or Jointed Pipe.

- Allows to make Perforations and Acid Stimulation in the same run.

- Available in Many Phasing Patterns, shot density and orifice diameters.

- Built in Carbide Tungsten Protective Plates to protect the tool body from washback.

- Tool Body: 1.9” OD.

- Can Perf on 2 3/8” – 3 ½”.

- Up to 6 SPF.

Sand Jet Cutter

The Sand Jet Cutter is a tool that use sand slurry to completely sever casing or tubing avoiding to use explosives or harsh chemicals.

Rather than using an indexing tool or downhole motor in order to cut radially, the rotating head tool spins when under high pressure water, which is certainly the case in the sand jet method Christensen Roder employs.

FEATURES

- Uses sand slurry to completely sever casing or tubing

- No explosives or harsh chemicals

- Coiled tubing or jointed pipe conveyed

- Smooth cut is easier to recover.

- Can be run through restrictions

- Surface test can be done in advance prior to determine to cutting time.

Sand Gun

The Sand Gun is an equipment system expertly designed to perform sand jet perforating and cutting operations in a whole new way. The Sand Gun was developed in order to consolidate operations in a perforating job into one convenient “package”.

FEATURES

- Blends chemical and injects sand into pressure line.

- No Frac Pump required.

- No sand passes through the fluid end of the pump.

- Continuos pump rate.

- Compact design.

- Easy and simple maintenance.

- Trailer or skid mounted.

Español

Español