The development of shale gas reservoir required innovative technology, tools and unconventional techniques. In this context, the application of the Frac Plugs opens a new alternative in completion techniques.

Christensen Roder provides a wide range listing of plugs technologies that meets the attend each operation demands, seeking to optimize operating times, ensure a successful operation and decrease operational costs.

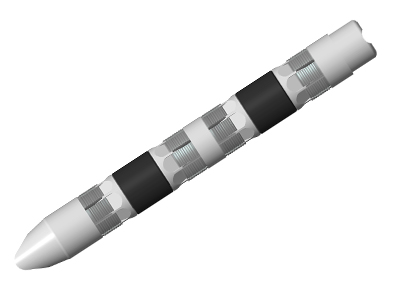

Dissolvable Frac Plug X Factor

The dissovable plug X Factor is a 100% Magnesium Composite Material water soluble. Built in Metal Seal or Fully Degradable Rubber Seal.

Christensen Roder offer the most customizable Dissovable Plug in the market providing operational and economical advantages to the client. The technology of this Plug allows to manufacture them with a specific dissolution rate for each particular project.

FEATURES

- 100% Magnesium Composite Material

- Completely Water Soluble

- Dissolves in <1% Chloride and Fresh water at 200°F or Higher

- Customizable Dissolve Times

- Customized OD and Bore ID For Troubled Wells

- Uses Standard Baker #10 and #20 Setting Tools

- Can Be Designed For Unconventional Applications

- Environmentally Safe

- Only Tool with Fully Degradable Rubber Seal

- Max Running Speeds 250’ –300’ per MinuteMaterial

- Tested for 10K psi dif pressure

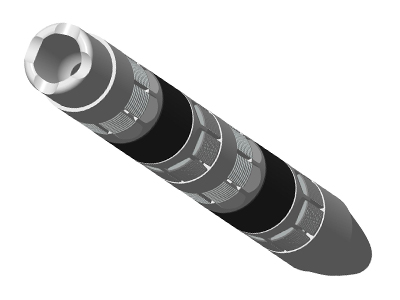

Dissolvable Frac Plug Double XL

The dissovable plug X Factor is a 100% Magnesium Composite Material water soluble. Built in Metal Seal or Fully Degradable Rubber Seal. The reduced OD allows to pass through restrictions. A double seal is provided to stand the conventional diferential pressures.

Christensen Roder offer the most customizable Dissovable Plug in the market providing operational and economical advantages to the client. The technology of this Plug allows to manufacture them with a specific dissolution rate for each particular project.

FEATURES

- Slim design to pass though restriccions

- Double seal to attend frac pressures

- 100% Magnesium Composite Material

- Completely Water Soluble

- Dissolves in <1% Chloride and Fresh water at 200°F or Higher

- Customizable Dissolve Times

- Customized OD and Bore ID For Troubled Wells

- Uses Standard Baker #10 and #20 Setting Tools

- Can Be Designed For Unconventional Applications

- Environmentally Safe

- Only Tool with Fully Degradable Rubber Seal

- Max Running Speeds 250’ –300’ per MinuteMaterial

- Tested for 10K psi dif pressure

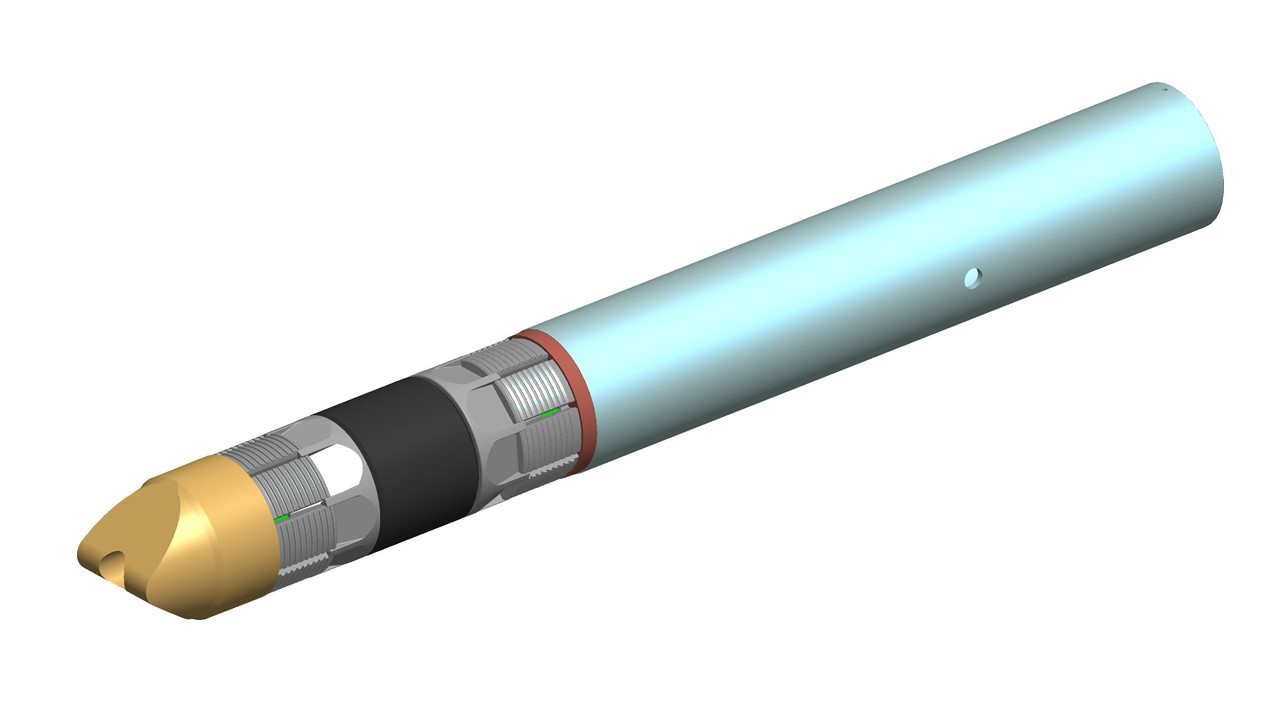

Dissovable Plug Mini XP

The Mini XP Plug tubing plug designed to perform pressure tubing test as well as isolate the direct to control the pressure from the well delivering safe conditions at surface to POOH the string.

The manufacture of Mini XP plugs is made up to the dimensions, the environment where the plug will be set and selaing time required.

FEATURES

- 100% Magnesium Composite Material

- Completely Water Soluble

- Dissolves in <1% Chloride and Fresh water at 200°F or Higher

- Customizable Dissolve Times

- Customized OD and Bore ID For Troubled Wells

- Uses Standard Baker #5 Setting Tools

- Can Be Designed For Unconventional Applications

- Environmentally Safe

- Only Tool with Fully Degradable Rubber Seal

- Max Running Speeds 250’ –300’ per MinuteMaterial

- Tested for 10K psi dif pressure

- Fast dissolution by adding HCl or 8% KCl

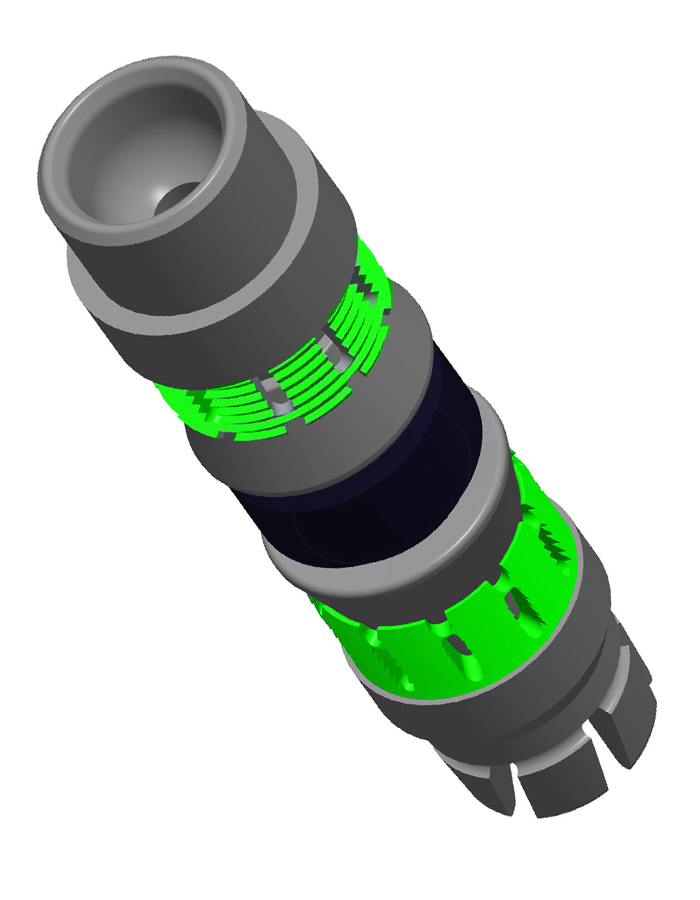

Composite Plug Xtreme

The Xtreme plug is a high reliable plug in drill-out times and seal.

FEATURES

- High temperature thermoplastics replace brass and other non-ferrous metals.

- Industry standard HNBR sealing element for maximum sealing reliability.

- Machined cast iron slips guaranteed to hold in any condition.

- Less material equals less trash in well bore.

- Unique locking design prevents mill from losing bite on next plug.

- Lighter smaller pieces return to surface using less viscous fluid.

- Average mill out times 8 – 12 minutes.

Español

Español